(→Cables) |

|||

| (16 intermediate revisions by 2 users not shown) | |||

| Line 3: | Line 3: | ||

On the servo's shaft are magnets, attached at specific locations. Sequences and combinations of magnetic fields generated within the motor drive the magnets and give precise control over the shaft's rotation. Also on the servo’s shaft is a glass disc with very fine lines on it. The optical encoder counts those lines as it rotates with the motor, the information is fed back to the controller, and through a host of feedback loops and logic circuits, produces the desired motion. | On the servo's shaft are magnets, attached at specific locations. Sequences and combinations of magnetic fields generated within the motor drive the magnets and give precise control over the shaft's rotation. Also on the servo’s shaft is a glass disc with very fine lines on it. The optical encoder counts those lines as it rotates with the motor, the information is fed back to the controller, and through a host of feedback loops and logic circuits, produces the desired motion. | ||

| − | == | + | == Part Numbers == |

| + | |||

| + | [[File:Zservo3.jpg|400px]] | ||

| + | |||

| + | [[File:Zservo2.jpg|400px]] | ||

| + | |||

| + | [[File:Zservo4.jpg|400px]] | ||

| + | |||

| + | [[File:Zservo5.jpg|400px]] | ||

| + | |||

| + | [[File:10Cservo2.jpg|400px]] | ||

| + | |||

The following part numbers note some common Dynetic Systems servos used in Techno CNC routers: | The following part numbers note some common Dynetic Systems servos used in Techno CNC routers: | ||

| Line 34: | Line 45: | ||

* PC Brushless X/Y Motor = HZ2600M067B607B | * PC Brushless X/Y Motor = HZ2600M067B607B | ||

* PC Brushless Z Motor = HZ2600M067B617B | * PC Brushless Z Motor = HZ2600M067B617B | ||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

== Cables == | == Cables == | ||

| − | + | Note that an [[RG Series]] machine requires special cables for the controller mainboard. | |

| − | [[ | + | |

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | * HX1700M1016-CE = 16 foot, both cables | |

| + | * HX1700M1025-CE = 25 foot, both cables | ||

| + | * Cable set HX1700M1025-CEX = 20 foot | ||

| + | * 15.5' Motor/Encoder Cable HX1700M1015.5-CE | ||

| + | * 15.5' Motor/Encoder Cable HX1700M1015.5-LC | ||

| + | * 16' Motor/Encoder Cable HX1700M1016-CE both cables | ||

| + | * 20' Motor/Encoder Cable HX1700M1020-CE | ||

| + | * 25' Motor/Encoder Cable HX1700M1025-CE both cables | ||

| + | * 31' Motor/Encoder Cable HX1700M1031-CE | ||

| + | * 35' Motor/Encoder Cable HX1700M1035-CE | ||

Latest revision as of 12:32, 10 December 2010

A servo motor is usually comprised of the drive section and the encoder. A servo motor is much smoother in motion than a comparable stepper motor, and will have a much higher resolution for position control. While the servo family is further divided into AC and DC types, most all the servos we use are brushed DC.

On the servo's shaft are magnets, attached at specific locations. Sequences and combinations of magnetic fields generated within the motor drive the magnets and give precise control over the shaft's rotation. Also on the servo’s shaft is a glass disc with very fine lines on it. The optical encoder counts those lines as it rotates with the motor, the information is fed back to the controller, and through a host of feedback loops and logic circuits, produces the desired motion.

Contents

Part Numbers

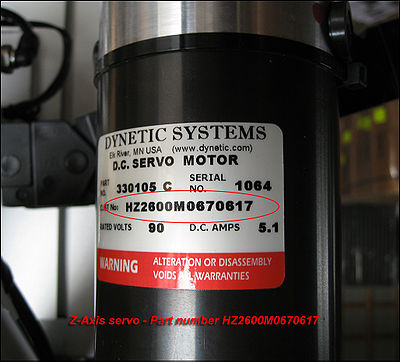

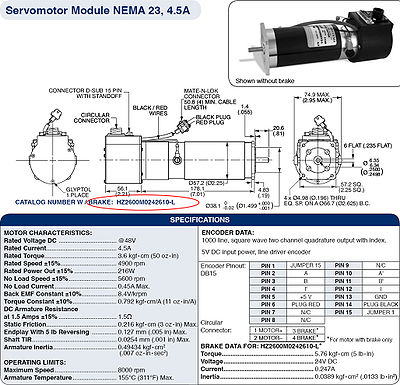

The following part numbers note some common Dynetic Systems servos used in Techno CNC routers:

Servos for: LC+, RG 4896/5050, 59120, 78120

- X/Y Motor Assembly - HZ2600M0670607

- (motor H50R10-067 / encoder H90Z46-SRV90C-1)

- Z-Axis Motor Assembly - HZ2600M0670617

- (motor H50R11-067 / encoder H90Z46-SRV90D-1)

Servos for: LC 4896; 5050; 59120

- X/Y Motor Assembly - HZ2600M0243600-L

- (motor H50R11-0243 / encoder H90Z46-SRV90C-1)

- Z-Axis Motor Assembly - HZ2600M0243610-L (for LC and also for Servo Davinci)

- (motor H50R11-0243 / encoder H90Z46-SRV90D-1)

Servos for: PC 6050

- X/Y Motor Assembly - ?????????????

- (motor H50M30-3485M4463 / encoder H90Z46-SRV90C-1)

- Z-Axis Motor Assembly - HZ2600M067B617

- (motor H50M30-3485B4475 / encoder H90Z46-SRV90D-1)

Other Servo motors

- LP, LC, 3A X/Y Motor = HZ2600M0243600-L

- MP LC 4.5A X/Y Motor = HZ2600M1050XY3-L

- HP LC+ 5.1A X/Y Motor = HZ2600M0670607

- PC Brushless X/Y Motor = HZ2600M067B607B

- PC Brushless Z Motor = HZ2600M067B617B

Cables

Note that an RG Series machine requires special cables for the controller mainboard.

- HX1700M1016-CE = 16 foot, both cables

- HX1700M1025-CE = 25 foot, both cables

- Cable set HX1700M1025-CEX = 20 foot

- 15.5' Motor/Encoder Cable HX1700M1015.5-CE

- 15.5' Motor/Encoder Cable HX1700M1015.5-LC

- 16' Motor/Encoder Cable HX1700M1016-CE both cables

- 20' Motor/Encoder Cable HX1700M1020-CE

- 25' Motor/Encoder Cable HX1700M1025-CE both cables

- 31' Motor/Encoder Cable HX1700M1031-CE

- 35' Motor/Encoder Cable HX1700M1035-CE