(fixed backwards terminology.) |

|||

| (17 intermediate revisions by 2 users not shown) | |||

| Line 1: | Line 1: | ||

| − | + | An inverter is an electrical device that converts direct current (DC) to alternating current (AC). It may be single phase or 3 phase, and powers the machine’s systems and motors. It is so named because early mechanical AC to DC converters were modified and made to work in reverse, and thus were "inverted", to convert DC to AC. | |

| − | + | ||

== Inverter Basics == | == Inverter Basics == | ||

| Line 7: | Line 6: | ||

Shown here are 2 inverters, an Altivar 31 (note that it says "Altivar 31" below the blue Telemechanique Logo). | Shown here are 2 inverters, an Altivar 31 (note that it says "Altivar 31" below the blue Telemechanique Logo). | ||

| − | The second inverter is a Teco FM100, which we no longer use though you may still encounter | + | The second inverter is a Teco FM100, which we no longer use though you may still encounter these. |

Important considerations in replacing inverters are: | Important considerations in replacing inverters are: | ||

* Phase (single phase or 3 phase?) | * Phase (single phase or 3 phase?) | ||

| Line 22: | Line 21: | ||

To test spindle, short the screws marked " ''' +24V ''' " and " '''LI1''' " , the '''small''' red and black wires above | To test spindle, short the screws marked " ''' +24V ''' " and " '''LI1''' " , the '''small''' red and black wires above | ||

| − | To '''change the direction of spindle rotation''', swap any 2 of the | + | To '''change the direction of spindle rotation''', swap any 2 of the 3 power wires that go from the inverter to the spindle (excluding the green/ground!). These wires are usually but not always on the right side. Consult a licensed electrician. |

[[File:12_2tecoinvert.jpg]] | [[File:12_2tecoinvert.jpg]] | ||

| + | |||

| + | In some setups, the Inverter may be located somewhere other than on the machine, such as on a wall, as in this case: | ||

| + | [[File:Inverter_wall.jpg]] | ||

| Line 30: | Line 32: | ||

Electronics Part Number | Electronics Part Number | ||

| − | * | + | *05 HP/230v = H24Z40-IV5HP230V |

| − | * | + | *10 HP/230v = H24Z40-IV10HP230 |

| − | * | + | *15 HP/230v = H24Z40-IV15HP230 |

| − | + | ||

| − | + | ||

| − | + | ||

| − | * | + | * 05 HP Inverter Conduit Box = H24M10-VW3A31815 |

| − | * | + | * 10 HP Inverter Conduit Box = H24M10-VW3A31816 |

== Programming Inverters == | == Programming Inverters == | ||

| Line 63: | Line 62: | ||

=== Alternate (Long) method === | === Alternate (Long) method === | ||

# Follow above steps | # Follow above steps | ||

| − | # My Device | + | # (highlight)My Device |

# Click "Connect the Device" button on toolbar | # Click "Connect the Device" button on toolbar | ||

## Ingnore warning | ## Ingnore warning | ||

| Line 74: | Line 73: | ||

#### Accel should be ''' 2 ''' or more. this is the acceleration rate. | #### Accel should be ''' 2 ''' or more. this is the acceleration rate. | ||

#### Decel should be ''' 0.5 ''' This is set to a very low value because adaptive deceleration is used. You may try increasing the value of this. I would probably not use a value greater than 3.0. The larger the value, the longer it will take for the spindle to stop. | #### Decel should be ''' 0.5 ''' This is set to a very low value because adaptive deceleration is used. You may try increasing the value of this. I would probably not use a value greater than 3.0. The larger the value, the longer it will take for the spindle to stop. | ||

| + | ####SdC = 0.5 | ||

| + | ####brA = Yes | ||

### Frequency range | ### Frequency range | ||

#### TFR (first) | #### TFR (first) | ||

| Line 96: | Line 97: | ||

[[File:12_5inverter_prog.jpg]] | [[File:12_5inverter_prog.jpg]] | ||

| + | ::from drC menu : | ||

| + | ::::'''tFr''' - 300 set this BEFORE setting HSP and LSP. | ||

::From the set menu: | ::From the set menu: | ||

::::'''ACC''' - this may be set between 0.5 and 3 this is the acceleration rate. | ::::'''ACC''' - this may be set between 0.5 and 3 this is the acceleration rate. | ||

| Line 101: | Line 104: | ||

::::'''LSP''' - 100 | ::::'''LSP''' - 100 | ||

::::'''HSP''' - 300 This is the maximum frequency | ::::'''HSP''' - 300 This is the maximum frequency | ||

| − | |||

::::'''ITH''' - set this to the current on the motor nameplate. | ::::'''ITH''' - set this to the current on the motor nameplate. | ||

::from drC menu : | ::from drC menu : | ||

| Line 109: | Line 111: | ||

::::'''nSP''' - 18.00 | ::::'''nSP''' - 18.00 | ||

::::'''COS''' - this is the motor power factor as indicated on the motor nameplate. It could be 0.8 for your spindle | ::::'''COS''' - this is the motor power factor as indicated on the motor nameplate. It could be 0.8 for your spindle | ||

| − | ::::'''UFT''' - constant | + | ::::'''UFT''' - constant (the option to choose is "L") |

::::'''tFr''' - 300 | ::::'''tFr''' - 300 | ||

::From the I-O menu: - you shouldn't have to change this, this only affects the on/off control signal to the spindle | ::From the I-O menu: - you shouldn't have to change this, this only affects the on/off control signal to the spindle | ||

::::'''tCC''' - 2C | ::::'''tCC''' - 2C | ||

| − | Remember to press "Enter" after each entry is made. | + | Remember to press "Enter" after each entry is made to save the entered value. |

:Save Configurations: | :Save Configurations: | ||

::drC menu > SCS > Str 1 | ::drC menu > SCS > Str 1 | ||

| + | |||

[[Category:Electronics]] | [[Category:Electronics]] | ||

Latest revision as of 06:21, 3 October 2011

An inverter is an electrical device that converts direct current (DC) to alternating current (AC). It may be single phase or 3 phase, and powers the machine’s systems and motors. It is so named because early mechanical AC to DC converters were modified and made to work in reverse, and thus were "inverted", to convert DC to AC.

Contents

Inverter Basics

Inverters usually need to be programmed with values obtained from the name plate on the spindle (get pic) of the machine into which the inverter is to be installed.

Shown here are 2 inverters, an Altivar 31 (note that it says "Altivar 31" below the blue Telemechanique Logo). The second inverter is a Teco FM100, which we no longer use though you may still encounter these. Important considerations in replacing inverters are:

- Phase (single phase or 3 phase?)

- ATC (does machine have an automatic tool changer?)

- Horsepower

- Voltage

- Amperage

To test spindle, short the screws marked " +24V " and " LI1 " , the small red and black wires above

To change the direction of spindle rotation, swap any 2 of the 3 power wires that go from the inverter to the spindle (excluding the green/ground!). These wires are usually but not always on the right side. Consult a licensed electrician.

In some setups, the Inverter may be located somewhere other than on the machine, such as on a wall, as in this case:

Part Numbers for Telemechanique Altivar 31

Electronics Part Number

- 05 HP/230v = H24Z40-IV5HP230V

- 10 HP/230v = H24Z40-IV10HP230

- 15 HP/230v = H24Z40-IV15HP230

- 05 HP Inverter Conduit Box = H24M10-VW3A31815

- 10 HP Inverter Conduit Box = H24M10-VW3A31816

Programming Inverters

Required Tools

- Serial-to-RJ45 cable

- PowerSuite application

- Power leads

Quick Method

- Connect serial-to-RJ45 cable

- Start PowerSuite

- Click " i " button

- My Configurations

- Altivar Drives

- ATV31

- Altivar Drives

- My Configurations

- Find your inverter on the list

- Right-click + Download

- Alt-F at warning

- Click OK

If that method failed, try the longer method.

Alternate (Long) method

- Follow above steps

- (highlight)My Device

- Click "Connect the Device" button on toolbar

- Ingnore warning

- Explorer menu:

- Motor Control

- Motor Characteristics

- Input values from Spindle plaque

- Adjustments

- Accel / Decel

- Accel should be 2 or more. this is the acceleration rate.

- Decel should be 0.5 This is set to a very low value because adaptive deceleration is used. You may try increasing the value of this. I would probably not use a value greater than 3.0. The larger the value, the longer it will take for the spindle to stop.

- SdC = 0.5

- brA = Yes

- Frequency range

- TFR (first)

- HSP = 300 - This is the maximum frequency.

- LSP = 100

- ITH = set this to the current on the nameplate

- Thermal Protection - use Amperage value from spindle plaque

- Optimization

- Set voltage boost = 0

- UFT = Constant

- Accel / Decel

- Application Functions

- Preset speed values

- SP2

- 100

- 133

- 166 etc.

- SP2

- Preset speed values

- Motor Control

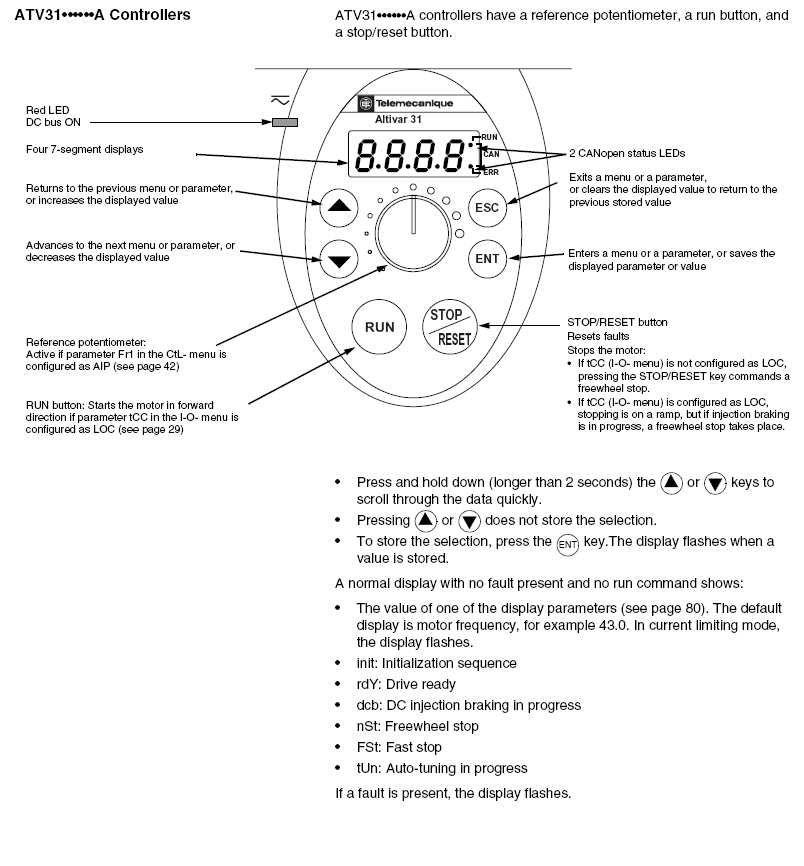

Programming thru Inverter Funtion Buttons

The Inverter's programming can be adjusted by the user via the function buttons on the inverter itself. Please contact Technical Support for help with these functionalities.

- from drC menu :

- tFr - 300 set this BEFORE setting HSP and LSP.

- From the set menu:

- ACC - this may be set between 0.5 and 3 this is the acceleration rate.

- DEC 0.5 - This is set to a very low value because adaptive deceleration is used. You may try increasing the value of this. I would probably not use a value greater than 3.0. The larger the value, the longer it will take for the spindle to stop.

- LSP - 100

- HSP - 300 This is the maximum frequency

- ITH - set this to the current on the motor nameplate.

- from drC menu :

- Un5 - set this to the voltage indicated on the motor nameplate.

- FR5 - 300

- nCr - set this to the current indicated on the motor nameplate.

- nSP - 18.00

- COS - this is the motor power factor as indicated on the motor nameplate. It could be 0.8 for your spindle

- UFT - constant (the option to choose is "L")

- tFr - 300

- From the I-O menu: - you shouldn't have to change this, this only affects the on/off control signal to the spindle

- tCC - 2C

- from drC menu :

Remember to press "Enter" after each entry is made to save the entered value.

- Save Configurations:

- drC menu > SCS > Str 1